Services

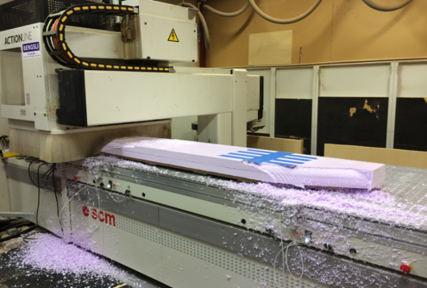

Our services include concept development, CNC model building and outer hull skin design with implementation of the FlowBow and FlowStern concept, in cooperation with naval architects or shipyards.

We can either help you with retrofitting the FlowBow and/or FlowStern to an existing hull or provide a new optimized hull shape to meet customer demands.

The design phase includes “in house” model testing to verify drag reduction, measure power consumption and do testing of sea keeping abilities. All “in house” model testing is monitored by “state of the art” data acquisition equipment from HBM/ Catman with sensors from HBM and Navilock.

Further verification, documentation and CFD can be done by Marintek/SINTEF Ocean in Norway.

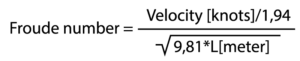

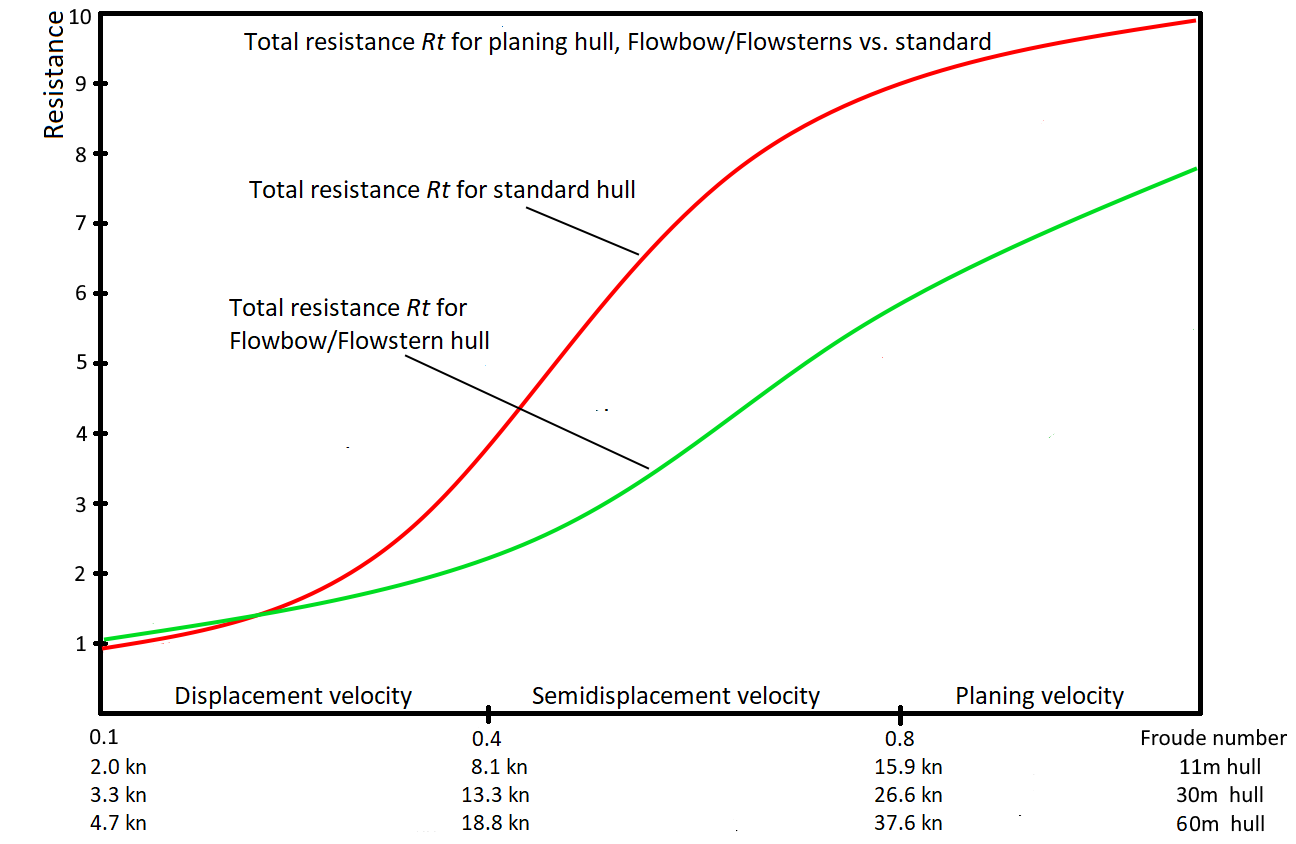

The graphs below show how the FlowBow and FlowStern concept reduces the total propulsion resistance for a typical displacement and planing vessel. Vessel speed is shown as Froude number and in knots for some given hull lengths.

To determine the vessels resistance in the graphs below it is essential to know the vessels velocity as Froude number. The Froude number is determined by the vessels velocity in knots and the vessels length in meter. (The resistance graphs above do not take into account the positive scaling effects due to frictional resistance RF)