Wave creation behind traditional, displacement and planing hulls

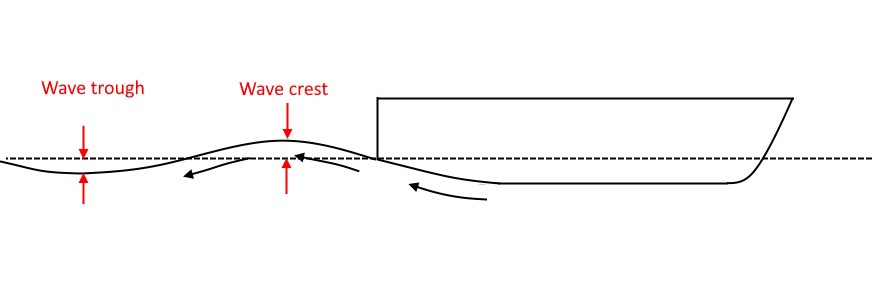

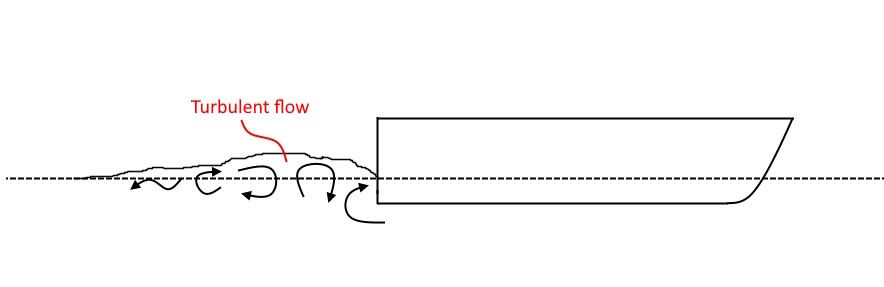

Wave creation behind traditional hulls

Prevents pressure differences and upward directed flow

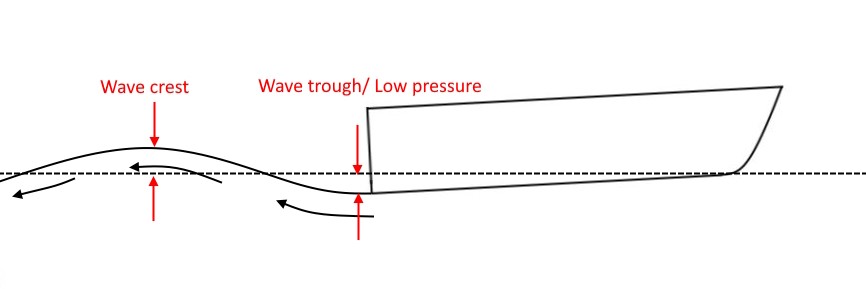

FlowStern counteracts turbulence and creation of stern wave behind the vessel over a broad speed range (from very slow all the way up to planning speeds).

The aft part of the hull guides water upward close to the waterline (like a displacement hull) where the aft foil is redirecting the upwardly directed water-flow to a horizontal direction, thereby preventing pressure differences between the water mass behind the vessel and the surrounding water mass. Further, the aft foil is preventing a stern down trim as the speed of the vessel increases.

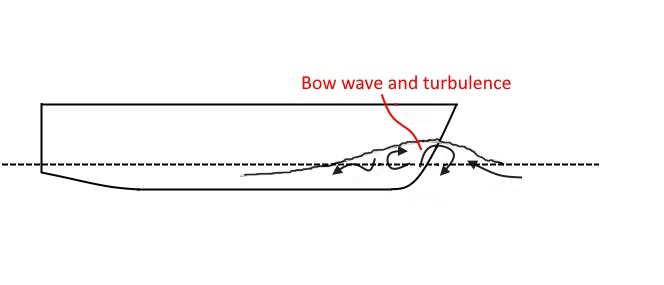

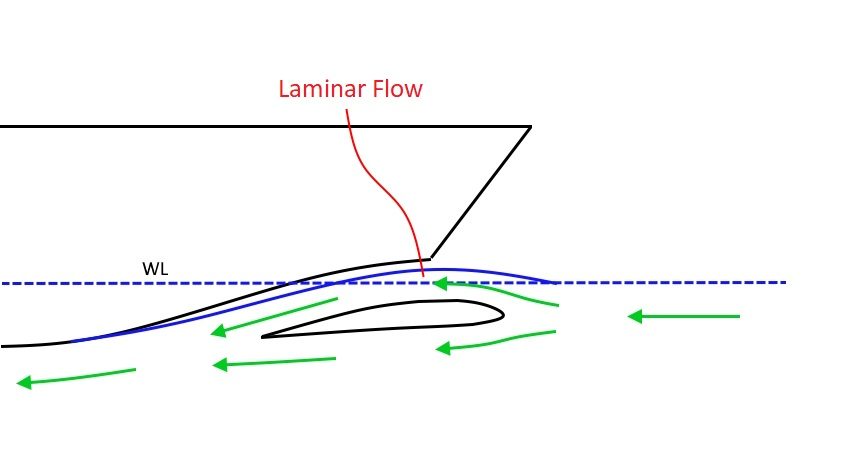

Bow wave

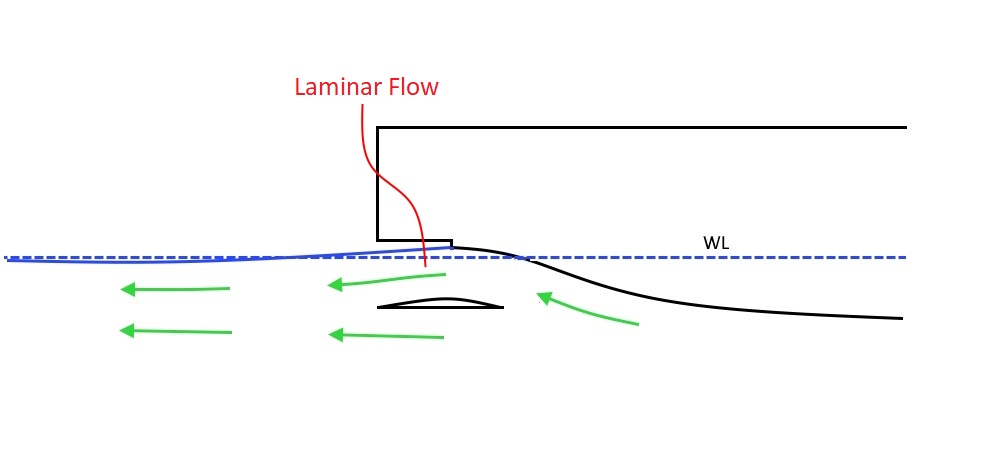

The FlowBow prevents the creation of a bow wave from the vessel. A streamlined body is placed in front of the hull. At operational speed, incoming water passes over the front body and further under the hull. A stationary wave trough, independent of speed, is created behind the front body, preventing the hull itself to displace incoming water. Since the incoming water passes freely with a laminar flow over the front body, there is minimum formation of a bow-wave as the velocity of the vessels increases.

Due to the vast reduction in wave making, the vessels total resistance can be lowered with up to 50%

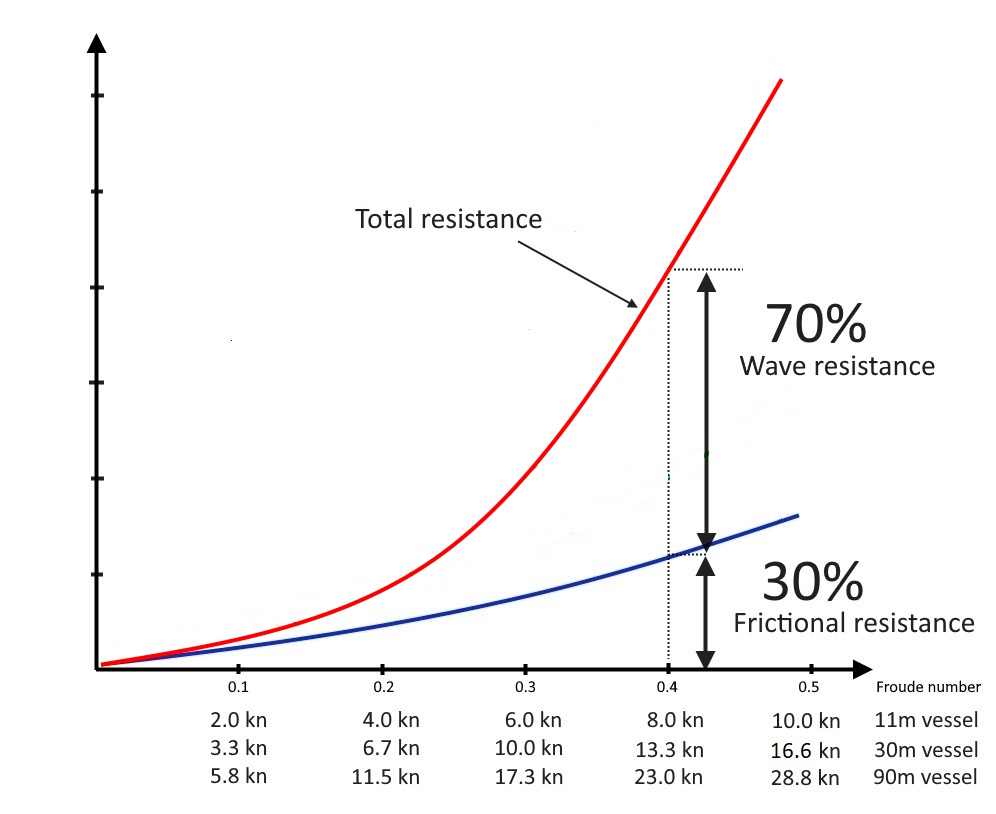

The vessels total resistance primarily consist of frictional resistance and wave resistance. At low velocity, resistance caused by friction between water and the hull is dominant. As velocity increases, the hull starts to generate waves. The wave resistance from wave making rises sharply with increasing velocity.

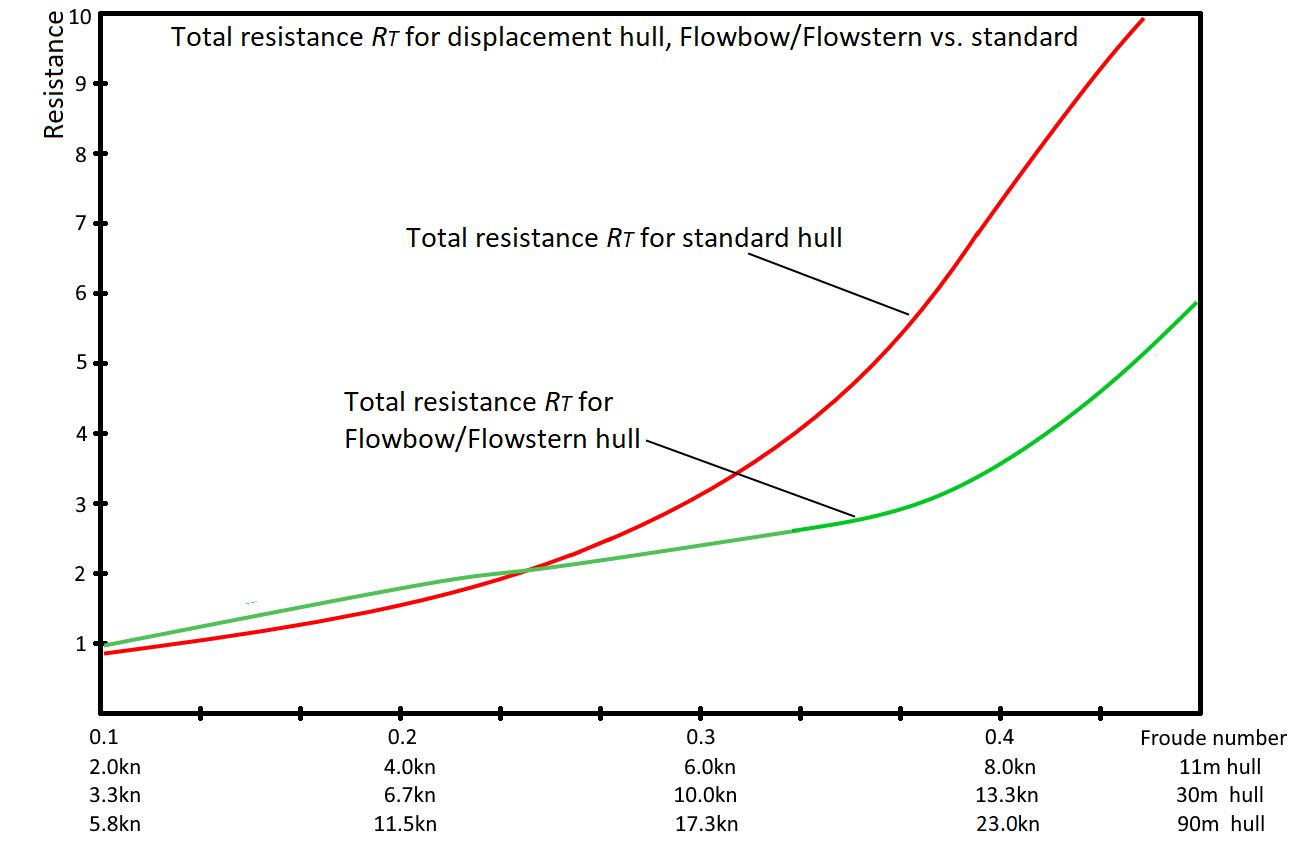

At high displacement velocity, the wave resistance typically contribute to 70 % of the vessels total resistance. The FlowBow and FlowStern technology significantly reduces wave making and wave resistance. A reduction in wave resistance by 60-70% consequently results in 40-50% reduction of the vessels total resistance (green graph).

The graphs above show the total resistance for a typical displacement hull compared to a FlowBow/ FlowStern hull. Depending of hull type the FlowBow/ FlowStern hull might have some small increase in resistance at low velocity below Froude number 0.25. Above this velocity, there is a significant reduction in resistance.

The hull shape influence the potential resistance reduction. A slender hull generates smaller waves. Consequently, the potential resistance reduction becomes less and can deviate from the shown graphs.

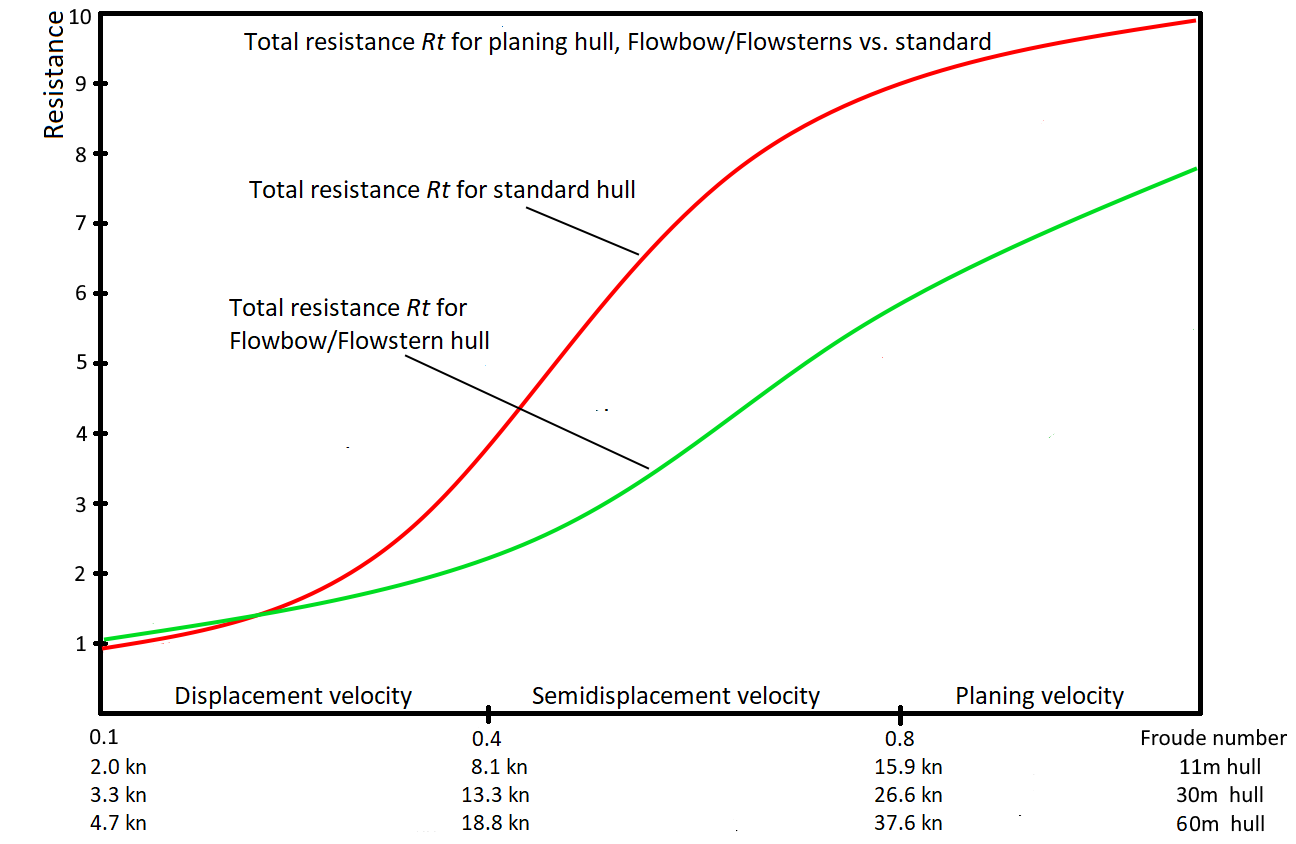

The graph above shows the total resistance for a typical planing hull compared to a FlowBow/ FlowStern hull. A traditional planing hull has poor performance before entering planing velocity, due to severe turbulence and wave making, especially in the transition zone from displacement to planning velocity.

Compare to a traditional planing hull, the FlowBow/ FlowStern hull eliminates most of the wave making, especially at high displacement and semi displacement velocity.

With FlowBow/ FlowStern technology, it then becomes possible to obtain good hull efficiency at semi displacement velocity.