FlowBow

Game changing hull design

Reduce fuel consumption and CO₂ emissions by up to 50%

The starboard vessel, seen in the direction of travel, has Flowbow® and Flowstern technology.

Barge

Barge with Flowbow® and Flowstern. Length: 8 meters, width: 5 meters, speed: 7,5 kn, Fn: 0,44

• Extend the range for electrically driven vessels

• Improve the vessel’s seakeeping abilities

• Enables cruising at a higher speed

5.0km/t corresponds to 7.7knots, 6.0 km/t corresponds to 9.2knots and 7.0km/t corresponds to 10.8 knots for 15m vessel

Use your mousewheel to zoom and drag with your mouse on the model to move it around!

Our patented Flowbow® and Flowstern technology contributes to a significant reduction in propulsion resistance by reducing the wave resistance. Fuel consumption and corresponding CO2 emissions can be reduced by as much as 50%.

For electrical driven vessels reduced resistance increases the range or lower the investment costs for batteries.

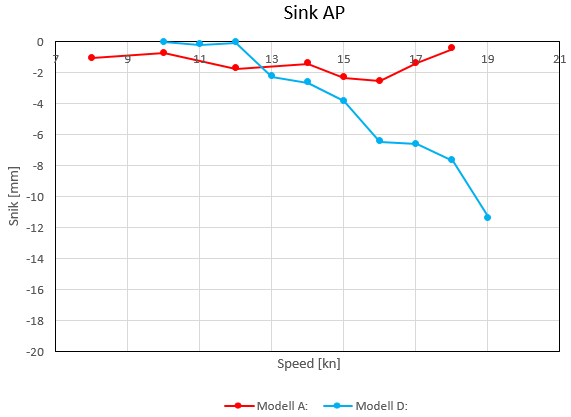

The Flowbow® and Flowstern concept greatly improves the seakeeping abilities by reducing the pitch motion, leading to higher comfort and less movement of the cargo. This also enable the vessel to cruise at higher speed in waves.

The Flowbow® and Flowstern greatly reduces the waves generated by the vessel, leading to less “washing” of shore areas and less waves to disturb smaller vessels and floating equipment.

How does it work?

Don’t waste energy on creating waves

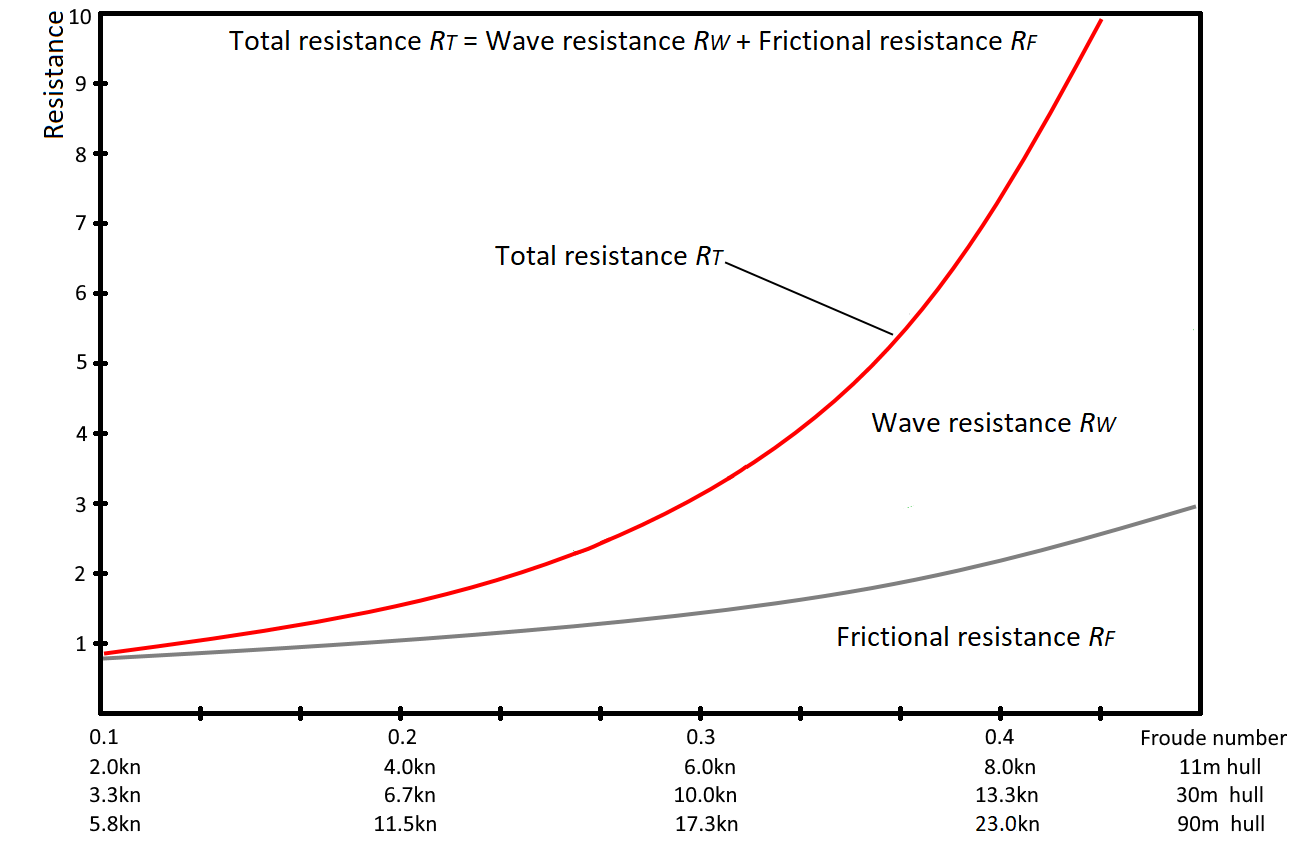

For vessels operated from high displacement up to planning velocity, resistance caused by wave making is by far the biggest contributor to the vessels total propulsion resistance.

Typical more than 2/3 of the resistance comes from wave resistance caused by wave making. Reducing the vessel’s wave making then becomes essential for reducing the vessels total resistance

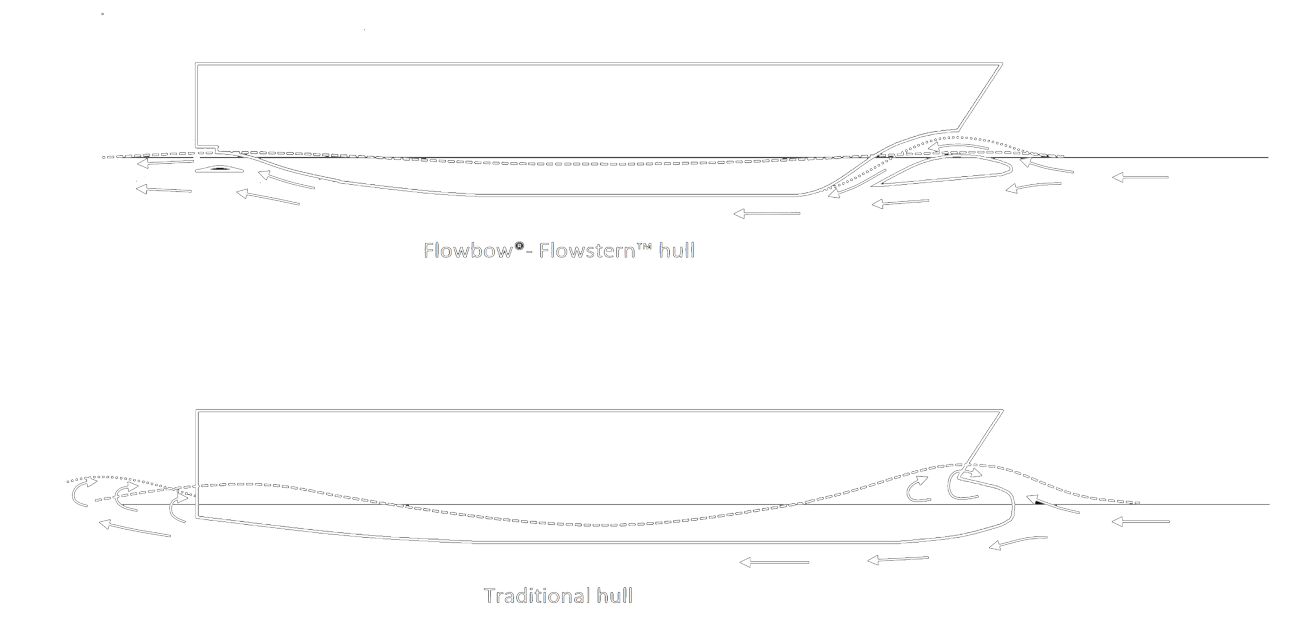

The working principle for Flowbow® and Flowstern

The Flowbow® prevents the creation of a bow wave from the vessel. A streamlined body is placed in front of the hull. At operational speed, incoming water passes over the front body and further under the hull. A stationary wave trough, independent of speed, is created behind the front body, preventing the hull itself to displace incoming water. Since the incoming water passes freely with a laminar flow over the front body, there is minimum formation of a bow-wave as the velocity of the vessels increases.

The Flowstern counteracts turbulence behind the hull and prevents creation of a stern wave.

Flowbow® and Flowstern – visual proof

The pictures below are showing the reduction of wave formation with Flowbow and Flowstern.

Standard bow

Standard stern

Flowbow

Flowstern

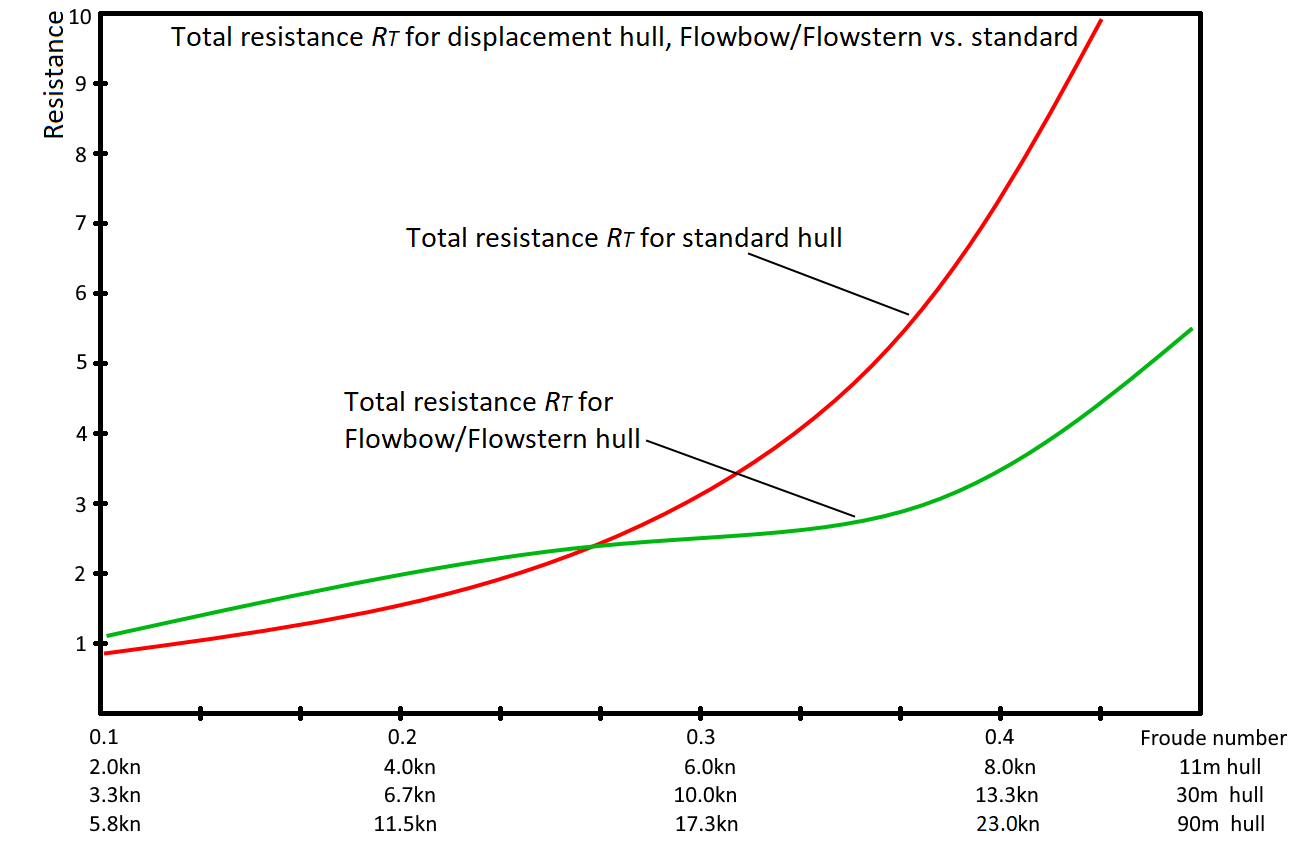

The vessels total resistance primarily consist of frictional and wave resistance. The Flowbow® and Flowstern technology significantly reduces the wave resistance. Due to the vast reduction in wave making, the vessels total resistance can be lowered with up to 50% at high displacement and semi displacement velocity.

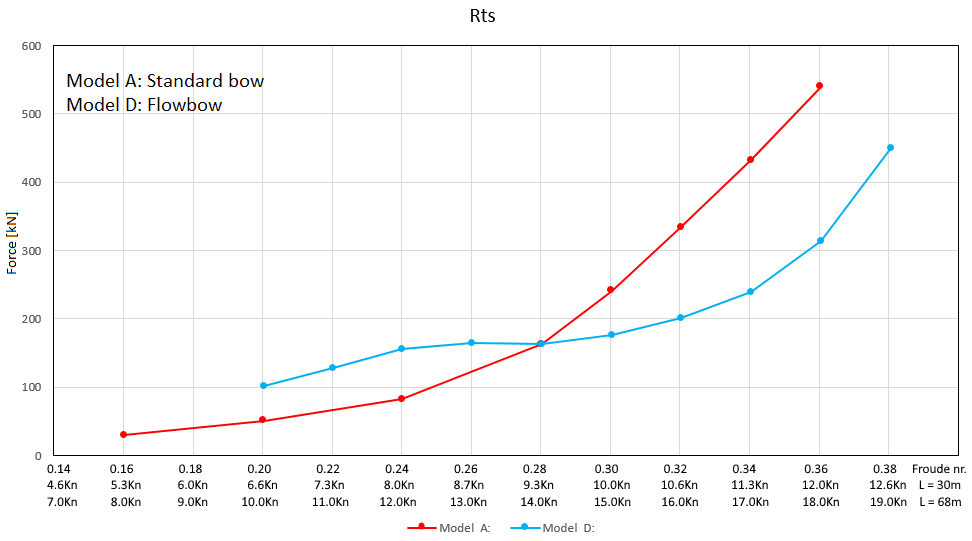

The graph below shows the total resistance for a traditional displacement hull. At low velocity the total resistance equals the frictional resistance. As the velocity increases the hull starts to generate waves. This contribute to a sharp rise in the wave resistance, leading to an exponential increase of the vessels total resistance.

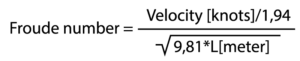

Velocity is shown as Froude number, with corresponding velocity in knots for 11, 30 and 90 meter hull length.

The graph below shows the total resistance for a typical Flowbow hull compared to a traditional displacement hull. At low velocity, the Flowbow hull has a higher resistance, but as velocity increases above Froude number 0.26-0.30, the Flowbow hull shows a significant reduction in resistance compared to the standard hull.

Hull types

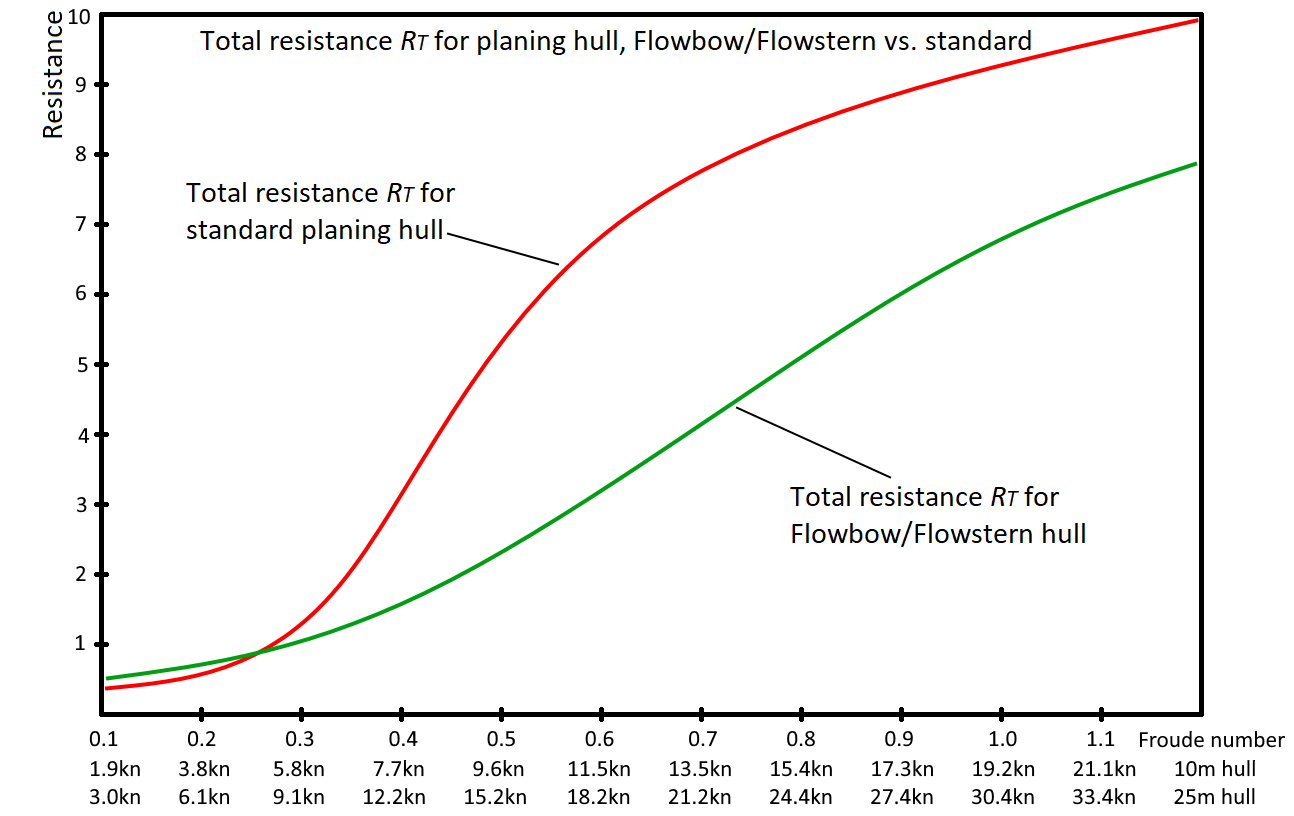

The Flowbow® and Flowstern concept can easily be adapted to a great variety of hull types and shapes including displacement, semi displacement, planing hulls, catamaran hulls and barges.

Depending on hull shape, reduction in resistance can be expected for vessels operated at velocities above Froude number 0.25-0.28. At high displacement and semi displacement velocity (Froude number 0.35-0.70) a resistance reduction of 40-55% can be expected. A slender fine entry or planning catamaran hull will typically achieve a reduction of 20-30% in the same speed range and above.

Verification

One of the leading European research laboratories, Marintek/SINTEF Ocean, has conducted towing tank tests of different Flowbow® designs to verify the resistance reduction achieved with the Flowbow® concept.

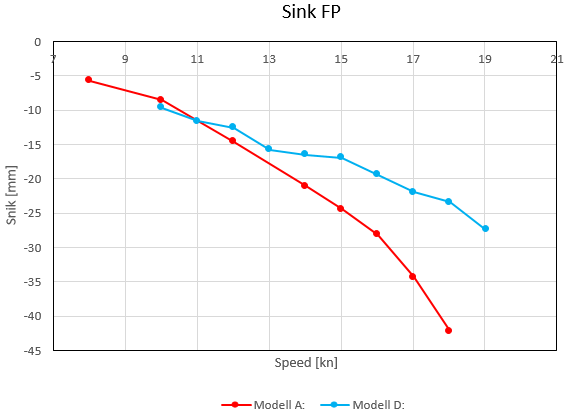

Resistance full scale 68 meter – Flowbow only

(i.e. no Flowstern modification)

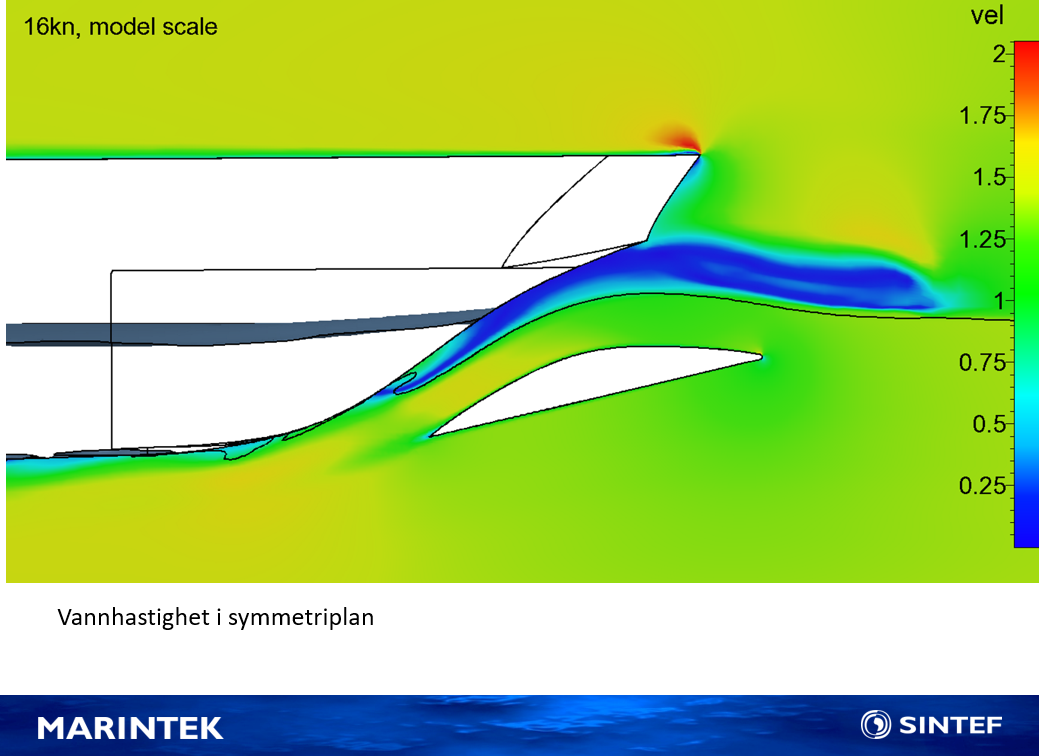

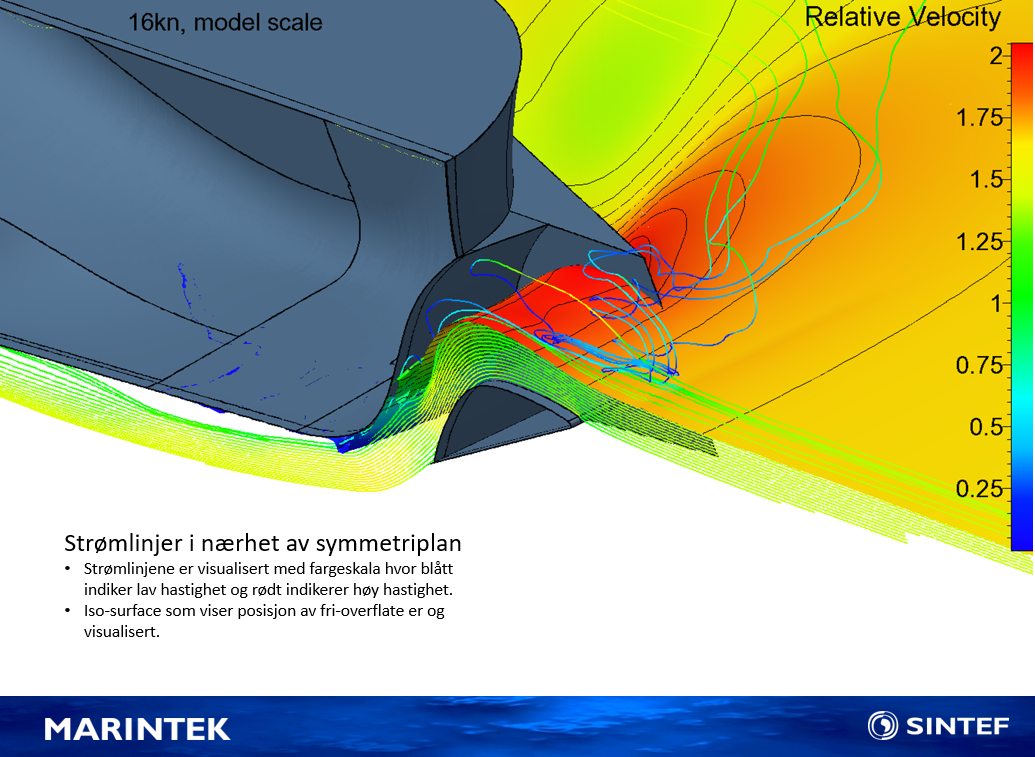

To further analyze the physics behind the Flowbow® concept, and to support the towing tank tests, several CFD analyses have been conducted.

All data from Marintek/SINTEF Ocean confirms a significand reduction in propulsion resistance and vast a reduction in wave formation. Our “in house” test results shows god resemblance with Marintek/SINTEF Ocean test results.

Services

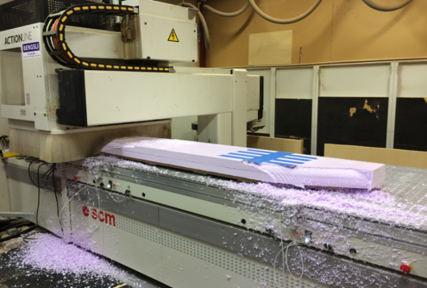

Our services include concept development, CNC model building and outer hull skin design with implementation of the Flowbow® and Flowstern concept, in cooperation with naval architects or shipyards.

We can either help you with retrofitting the Flowbow® and/or Flowstern to an existing hull or provide a new optimized hull shape to meet customer demands.

The design phase includes “in house” model testing to verify drag reduction, measure power consumption and do testing of sea keeping abilities. All “in house” model testing is monitored by “state of the art” data acquisition equipment from HBM/ Catman with sensors from HBM and Navilock.

Further verification, documentation and CFD can be done by Marintek/SINTEF Ocean in Norway.

The graphs below show how the Flowbow® and Flowstern concept reduces the total propulsion resistance for a typical displacement and planing vessel. Vessel speed is shown as Froude number and in knots for some given hull lengths.

To determine the vessels resistance in the graphs below it is essential to know the vessels velocity as Froude number. The Froude number is determined by the vessels velocity in knots and the vessels length in meter. (The resistance graphs below do not take into account the scaling effects for frictional resistance RF)

About us

Dag Rasmussen

Chief Executive Officer, Chairman of the Board

Dag graduated from Norwegian Univeristy of Science and Technology in Trondheim with a MSc degree in Marine Technology, specialising in Structural Engineering. He also holds a MSc in Shipping Trade and Finance from City University in London. He has since then worked in banking and as CEO of Rasmussengruppen.

Roar Moen

Inventor

- rmo@rasmussen.no

- +47 481 43 924

Roar Moen holds a Bachelor degree in Aeronautical engineering from University in Agder (UiA) in Kristiansand S, Norway. He is the creative mind behind new inventions and the inventor and designer of the Flowbow/Flowstern concept.

Gisle Rike

Sales Engineer

- gri@rasmussen.no

- +47 915 91 341

Gisle Rike holds an M. Sc. from the Norwegian University of Science and Technology (NTH). He has various experiences from project management, business development and operation from RASMUSSENGRUPPEN AS, Norwegian Rig Consultants AS and Maritime Tentech AS.

Lars Erik Larsson

Board member

Lars Erik Larsson has held the position of Group Lawyer in RASMUSSENGRUPPEN AS since 2017. In this position he has among other things been involved in contract negotiations and continuous juridical counseling. Mr. Larsson previously worked in KPMG Law (2014-2017) and Thommesen (2006-2014). He is also a member of the Board of Directors in AVANTOR AS and Shearwater GeoServices Holding AS.

Contact us

Rasmussen Maritime Design AS

Kirkegata 1, 4610 Kristiansand S, Norway

Phone: +47 38 12 22 00

rg@rasmussen.no